5 Wrenches to Rule Them All: Understanding Different Types of Wrenches

5 Wrenches to Rule Them All: Understanding Different Types of Wrenches

The Five Main Different Types of Wrenches

Wrenches are one of the most essential tools in any toolbox, and for good reason. These versatile tools tighten and loosen nuts, bolts, and other fasteners, making them indispensable for any DIY project or professional repair job. However, there are several different types of wrenches, and not all wrenches are created equal.

The different types of wrenches are designed for specific purposes. In this article, we’ll take a closer look at five of the most common types of wrenches and their unique features so that you can choose the right tool for your next project. So, let’s dive in and discover the five wrenches that truly rule them all!

Decoding the Mechanics of Wrenches: A Brief History and Overview

Wrenches have been an integral part of human civilization for centuries, dating back to the early days of mechanical engineering. These handy tools have come a long way since their humble beginnings, evolving into diverse designs to cater to various needs and applications.

When a wrench is used today, the general quality of the construction, alloy, and different steels used in the tool is exceptional. Good quality modern wrenches are sold at a very reasonable price, all things considered. They are designed to produce a precise amount of torque to the fastener. Modern manufacturing techniques are used, like heat treating and current induction with lasers. Manufacturers can get incredible hardness with the cutting edge and seration of modern tools.

A modern, well-built wrench has a long shelf life and could last your entire life if looked after.

With so many different wrench types and uses of wrenches available, it can get a little complicated. However, there are only five main types of wrenches. Most wrenches are often described under one of the following five categories.

1. The Ratchet Wrench

Ratchet Wrench is also different types of wrenches

Among the five most common wrenches, the ratchet wrench is the most widely used today. In most toolboxes worldwide, this hand tool is known as a combination wrench or the ordinary spanner. The ratchet wrench takes the common spanner, making it much easier to tighten and loosen fasteners. A combination wrench traditionally has a closed loop on one side (box-end) for hexagonal or square nuts, while the other end of the wrench has a U-shaped opening (open-end). The ratchet wrench is the same, except the closed loop has a mechanism that allows linear or rotary motion in only one direction. At the same time, it prevents motion in the opposite direction.

Its technologically advanced and distinctive mechanism allows for continuous fastening or loosening without repositioning the wrench after every turn. This time-saving and knuckle-saving feature makes it a favorite among professionals and DIY enthusiasts alike. It is ideal for tasks requiring multiple turns without repositioning the wrench.

If you only have an old-school spanner set or combination wrench in your toolbox, this is undoubtedly the single biggest improvement you can make to your tool collection. A ratchet wrench can be used to tighten or loosen hard-to-reach fasteners without readjusting the wrench after every turn or half-turn. Even better is a set of offset wrenches with an inbuilt ratchet system.

It is a genuine game changer that will save you so much time. When choosing a new wrench for the workshop that will save you inordinate amounts of frustration, the ratchet wrench is the king.

2. Next up is The Adjustable Wrench

Adjustable Wrench Different types of wrenches

This hand tool is often referred to as the “toolbox essential.” It is also known as a crescent wrench. Its adjustable jaw can fit various nut and bolt sizes, making it a versatile option for multiple tasks. Its ergonomic design and ease of use make it a popular choice for amateurs and experts.

Having an adjustable wrench in your toolbox is a no-brainer. The wrench head can be adjusted to fit the fastener without searching for an exact fitting spanner. Modern adjustable wrenches can even be had with a ratchet mechanism like the ratchet wrench above. However, I have found that I don’t use the ratchet mechanism on this type of tool in most situations.

However, these new adjustable wrenches are available with a ratchet mechanism that can be used in the closed position. Choosing a wrench with the ratchet mechanism makes sense, as you have a tool with a little more versatility.

This wrench makes DIY jobs with a weird fastener size relatively pain-free. Carrying your entire toolbox can be a pain when you have multiple jobs around the house. Taking one adjustable wrench with you is often the more straightforward solution. They aren’t the last word in accuracy, but modern adjustable wrenches are pretty good. Just don’t use this tool when looking to do major torque-down work.

3. The Socket Wrench

Socket Wrench different type of wrenches

A socket wrench, on the other hand, takes multifunctionality to new heights. The socket wrench uses sockets. This tool consists of a handle and detachable sockets, enabling it to tackle a wide range of fastener sizes and shapes. Whether working on a bike or a car, the socket wrench has got you covered.

A socket wrench also has a ratchet mechanism and has so many different types and uses. A socket wrench is the go-to tool when applying more torque. Using a socket wrench in these circumstances will cause far less strain and fatigue than a standard spanner.

In many professional operations, a powered or air-powered socket wrench is used. I’m sure you’ve seen these tools in action when you go to get your tires changed. A powered socket wrench often removes and replaces your wheel bolts.

A torque wrench is also a common form of this tool. A torque wrench is needed when a specific torque is required to fasten down a bolt, nut, or lag screw. These tools have an internal mechanism that indicates when a particular torque is reached. Batteries even power modern socket wrenches, making fastening and unfastening an absolute breeze.

There are other forms of a socket wrench, like an impact wrench. An impact wrench provides a very high rotational torque. An impact wrench is used to turn rusted or difficult bolts. The impact wrench uses either air or electricity. Today, you can purchase very powerful cordless impact wrenches.

The socket wrench is a fundamental tool needed in your toolbox.

4. The Clamp Wrench

Clamp Wrench different types of wrenches

These wrenches are also commonly called locking pliers. For those particularly tough jobs, the clamping wrench comes to the rescue. Designed for heavy-duty applications, this wrench provides extra gripping power and leverage, ensuring that even the most stubborn fasteners can be easily loosened or tightened.

Other names for a clamping wrench are vise-grips, mole wrenches, or mole grips. The clamp wrench has the excellent advantage of being locked into position. This means you can grab hold of the part you are working with and let go of the tool if the wrench is clamped.

The wrench has an adjuster at the end of the handle so they can clamp various sizes. These clamps are primarily used in welding or similar applications but can easily be used as a makeshift adjustable wrench. The clamp wrench is perfect for stripped nuts, working on pipes, or some type of fastener that doesn’t have a traditional head.

Locking pliers are available with many different jaw styles, such as needle-nose pliers, wrenches, clamps, and various shapes to fix metal parts for welding. They also come in many sizes.

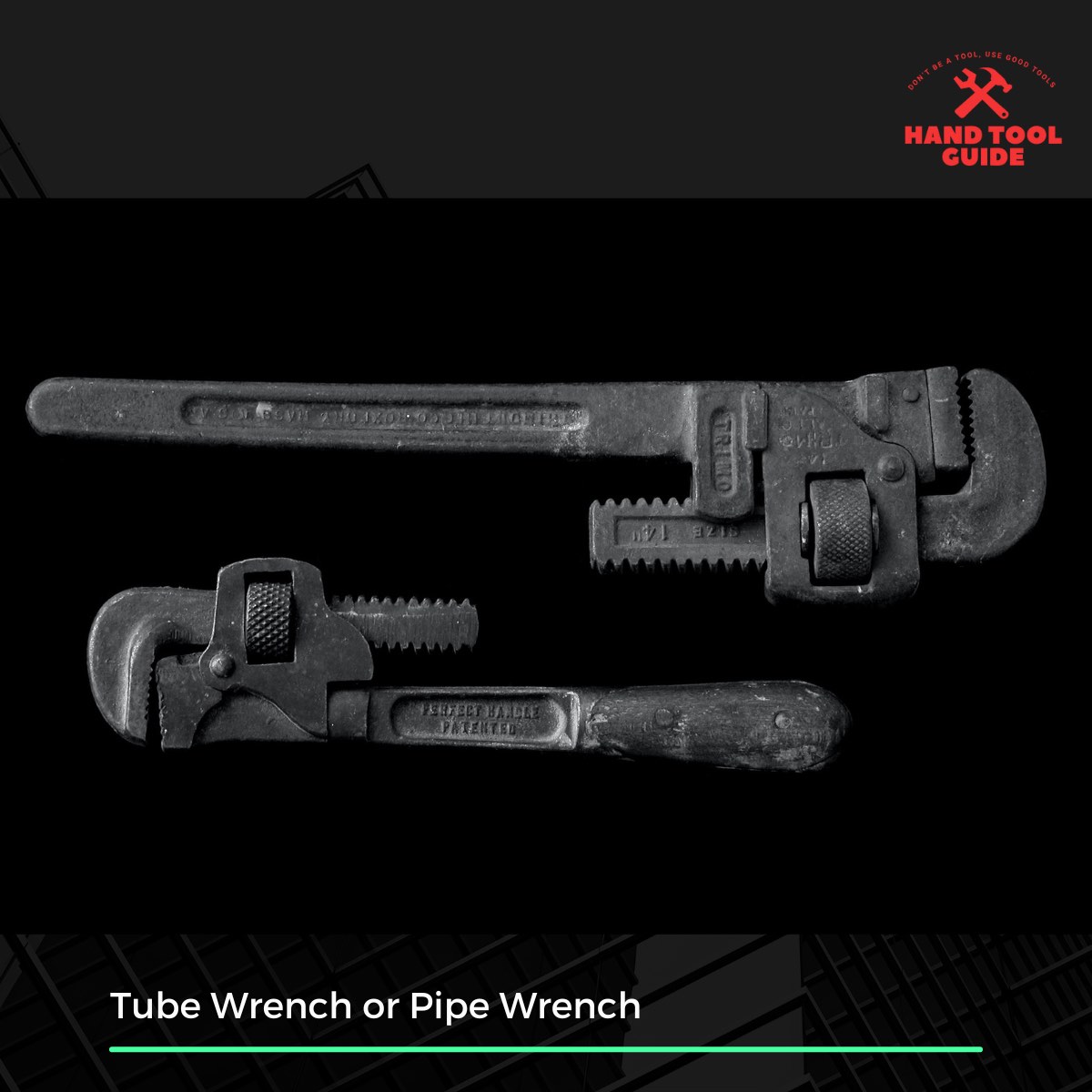

5. Tube Wrench or Pipe Wrench

Tube Wrench or Pipe Wrench different types of wrenches

Lastly, we have the tube wrench or Pipe Wrench. This wrench is a tool used mainly as an old staple in plumbing. Its unique design allows for a secure grip on rounded objects, making it indispensable for working with pipes and fittings, and other cylindrical objects.

The tube wrench may not be as well-known or widely used as the ratchet or adjustable wrench, but it’s a proper old staple.

The tube wrench features a long, thin handle with a jaw-like structure at the end. This jaw is designed to grip rounded objects securely, providing a tight hold that allows easy loosening or tightening. This is particularly important when working with pipes, as they can be difficult to grip with standard wrenches.

The tube wrench’s long handle also provides additional leverage, making it easier to tackle stubborn or rusted pipe fittings. This can save you time and frustration, allowing you to complete your plumbing project more efficiently.

Whether you’re a professional plumber or a DIY enthusiast, having a tube wrench in your toolbox is a must. Its unique design and secure grip make it the go-to tool for working with pipes and other rounded objects. So, the next time you’re faced with a plumbing project, remember to reach for the trusty tube wrench!

Choosing a wrench for you

Choosing the right tool for you

These five wrenches represent just a fraction of the vast array of options available on the market. Each type serves its unique purpose, from the impact wrench to the insulated wrench.

The ratchet wrench is a no-brainer in your toolbox. You will use this tool the most, which can be used for different purposes.

The adjustable wrench is a toolbox essential due to its versatility. Its adjustable jaw allows it to fit different sizes of nuts and bolts, making it a go-to option for various tasks. Its ergonomic design also ensures easy and comfortable use.

The socket wrench takes multifunctionality to a new level with its detachable sockets. This allows it to handle a wide range of fastener sizes and shapes, making it an indispensable tool for small and large projects when high torque may be needed.

For heavy-duty applications, the clamp wrench provides extra gripping power and leverage. It’s designed to handle tough jobs, ensuring that even the most stubborn fasteners can be easily loosened or tightened.

Lastly, the tube wrench is designed to work with rounded objects like pipes. Its unique design provides a secure grip, making it an essential tool for plumbing projects

Different types and uses of wrenches:

Different Types and Uses of Wrenches

There are hundreds of different wrenches, but they fall mainly into the above categories. For example, if you work in the automotive industry, you may want a flare nut wrench, a lug wrench, a spark plug wrench, a fan clutch wrench, and an oil filter wrench or strap wrench in your toolbox. However, most jobs in the automotive field can be done with standard wrenches if you have specialized sockets or a specific wrench size.

A professional plumber may have a basin wrench. A crowfoot wrench will help in tight spaces. If you work on bicycles often, you will probably want a pedal wrench, a cone wrench, and a dog bone wrench. Even with all these various types of wrenches, most jobs can be done with the standard common wrench types.

Understanding the structure and usage of the above wrenches can help you choose the right one for your needs and make your next project a breeze. Whether you’re a DIY enthusiast or a professional, having the proper wrench in your toolbox is essential for getting the job done efficiently and effectively.